FLEXIBLE POLIURETHANE

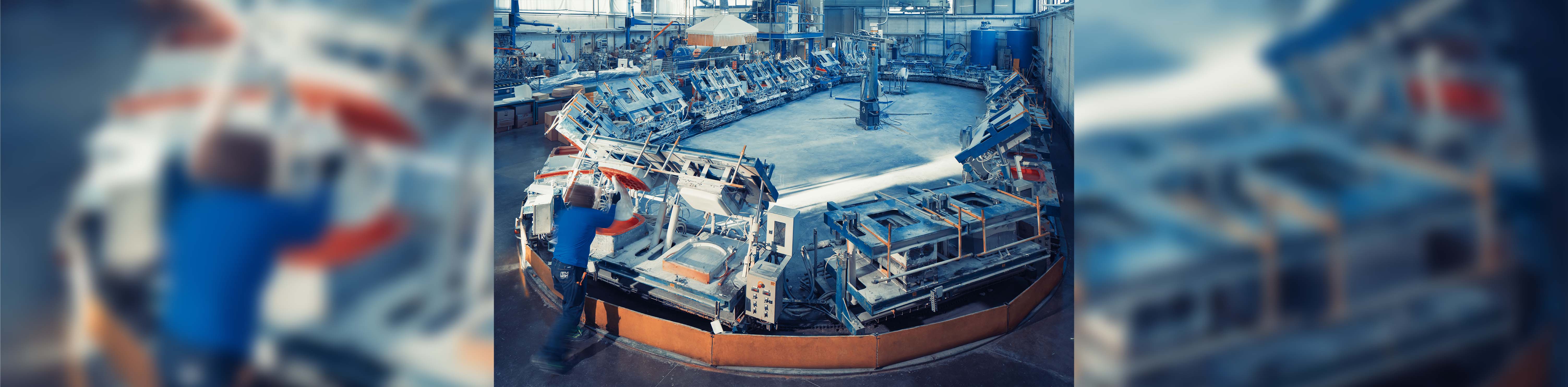

Abmflex has 11 production lines designed to produce flexible polyurethane, ensuring that the materials mantain elasticity and integrity even under constant stress. These advanced manufacturing systems are perfect to realize ergonomic and comfortable components, that adapt themselves uniformly to pressure and resist to the humidity and daily wear.

Furthermore, our sector dedicated to furnishing solutions stands out for the use of sophisticated technologies capable of processing polyurethane foams for items

of considerable dimensions, up to 40 kg. This allows us to realize large sofas, from 3 to 4 meters, combining superior comfort with innovative design.